Papyrus and Paper

Papyrus was made in Egypt dating back to the 4th millenium BCE and was the writing material of choice for thousands of years. Ultimately it was displaced by paper as the latter holds up better for long term storage in more humid climates. Paper manufacture is thought to have begun in China with some hemp-based papers dating back to the 8th century BCE (see Papermaking, Wikimedia). Paper making was introduced to the West by the Arabs in the mid 8th century after they captured a caravan of Chinese papermakers. It did not take long after that for paper to displace papyrus and parchment as a writing and printing material, especially with the introduction of the printing press, which required larger quantities of material for print. The first paper mill was opened in Spain around 1100 AD, and the Fabriano papermill in central Italy was founded in 1264 AD and is still in operation. Its papers have been used by Michelangelo Buonarrati, Georgia O'Keefe, Francis Bacon, Ludwig von Beethoven, and other notable figures.

Papyrus is related to paper but the method of production is considerably different. Both are products are based on plant cellulose (see Wood and Textiles) that is, by various methods, fashioned into thin sheets. Paper has become a material used for a wide variety of objects found in art museums around the world. Among these are drawings, water color paintings, pastels, prints, collages, sculptures and more.

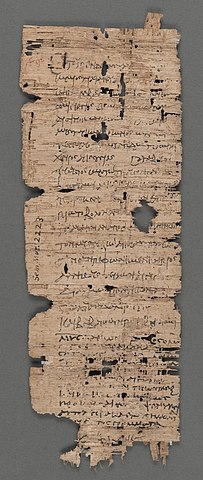

Papyrus

Papyrus is made from the stems of papyrus plants by first removing the woody outer coating. The fibrous pith is cut into strips which are then arranged in layers. A second layer is arranged on top of the first but perpendicular to it, similar to the method for producing plywood, for increasing the structural stability of the product. The process is not known exactly, but an adhesive may have been used between the layers and they may have been soaked in water for some time before layering. These layered sheets were then beaten to improve adhesion and dried under pressure. A step-by-step discussion of this can be found online at the Brooklyn Museum, Making Papyrus in the Conservation Lab. Papyrus has coarse appearance and the fibers used to make the sheets are often readily visible.

Papyrus is sensitive to moisture but some examples have lasted thousands of years in the dry climate of Egypt. Manuscripts written on papyrus do not last nearly so long in humid climates, such as Europe. In addition to parchment, which is derived from animal skins, some of the Dead Sea Scrolls were written on papyrus.

Paper

Paper is similar to papyrus in that it is based on plant fibers, but for paper these are more heavily processed. The original methods used by the Chinese and other Asian cultures also relied on plants whose fibrous stems could be harvested and processed.

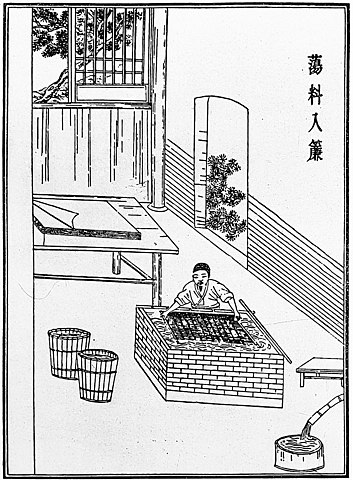

Ancient Asian Papermaking

The original production of paper began, as with papyrus, by harvesting suitable plant stalks. The stalks were peeled to remove the dark outer bark and then soaked in water. These were boiled to soften the fibers, after which they were cleaned of unwanted materials impurities. The fibers were collected and beaten to separate the fibers from one another. The cleaned and processed fibers were then re-suspended in water and the resulting slurry was placed on a screen attached to a wooden frame that would allow water to pass through but collect the pulp as a thin layer. This layer was then compressed to remove additional water and to bind the fibers together into a stable sheet. Once formed, the paper was dried and cut into the desired sizes and shapes.

Handmade papers are labor intensive and can be quite expensive. However, they offer the ability to customize the papers with a variety of textures, thicknesses, etc. The hand-making paper process can also be more environmentally friendly as it does not rely as heavily on chemical processes.

Making Paper from Wood

While making paper from wood fibers such as mulberry could be done using traditional hand methods, the introduction of industrial processes shifted the major commercial production of paper to the use of wood pulp and larger trees. The trees of choice are softwood conifers that yield longer cellulose fibers. While many of the steps parallel hand production methods, the industrial processes rely on heavy machinery to carry out the various steps on a large scale as well as on chemical treatments to process the wood chips into pulp or to modify the product once it is made.

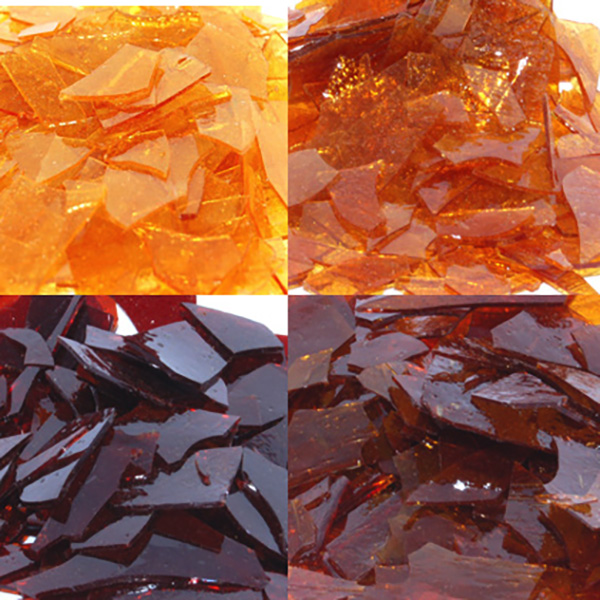

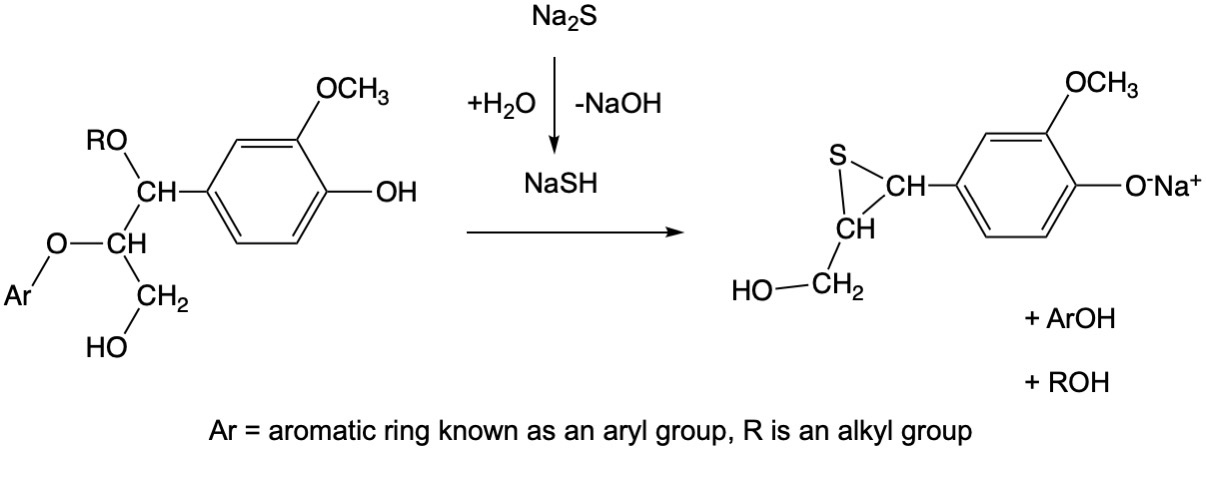

The bark on wood must be removed first, and then the wood is converted into pulp using either a mechanical process, in which the wood is chopped into small chips, or via chemical pulping, in which the wood chips are treated with sodium sulfide (Na2S) in strongly alkaline solution (Kraft process). The purpose of the sodium sulfide is to react with the lignin (see Wood for the structure of lignin) in the wood. This destroys the bonds between the lignin and cellulose and also solubilizes the lignin allowing it to be more easily separated. Mechanical pulping produces a higher yield of product, but it has shorter fibers and contains more impurities. This product is generally cheaper and of lower quality than that obtained by chemical pulping. Once the pulp is created it is bleached using one of a number of oxidizing agents such as chlorine, chlorine dioxide, oxygen, ozone or hydrogen peroxide. The goal of this step is to eliminate the remaining chromophores in the pulp to produce a whiter product.

In addition to producing papers directly from plants or trees, paper can also be made from fabrics. Cotton is perhaps the best known of those used for this purpose, and many artisan papermakers today used recycled clothing as a source of cellulose fibers for papermaking, hence the name cotton rag paper. In fact, cotton is a highly desirable component of papers, with conservators choosing papers that have at least a 50% cotton content for the best archival puposes.

Once the paper is produced, it can be treated in a number of ways to modify its properties for specialty applications. Sizing can be added to fill in the pores on the surface of the paper to make it smoother. As with fabric dyeing, the sizing materials must contain polar functional groups to help the compounds adhere to the polar cellulose molecules. Sizing agents include animal gelatin that has amino acids that can be bound to the cellulose via Al3+ ions in a fashion similar to mordanting in dyeing fabrics. Vegetable gelatins can also be used. A downside of the animal gelatins is that they tend to be acidic, which decreases the longevity of the paper.

Fillers may also be used to enhance physical properties of the paper such as its color, opacity, density and texture. White pigments such as kaolin clay, calcite (CaCO3) or titania (TiO2) may be added. The latter is the most expensive material but produces the brightest paper, while kaolin clay is the least expensive but also the least bright, with calcite being intermediate both in brightness and cost.

If you have ever browsed an art supply store, you will realize that there are a wide variety of papers that available depending on the application. Papers are manufactured specifically for use in drawings, watercolors, printing, etc. They will all have their own characteristic qualities of durability, permanence, finish, and tooth. Low acidity papers are required if the product is to be of archival quality as acidic functional groups tend to cause the degradation of the cellulose fibers resulting in yellowing and brittleness. Using basic compounds such as calcite will reduce the acidity in the manufactured material making it last longer but it will also protect the paper for a longer term against acid exposure in the atmosphere. The tooth of the paper refers to its macroscopic texture or roughness, which can readily be seen upon visual inspection - papers can be very smooth, as in newsprint, or rough as in some drawing papers. Papers designed specifially for calligraphy are treated so that ink will not bleed or feather when applied to the surface. Highly textured papers may find use in collages and other specialty applications.

In recent times, it has become popular to do scrapbooking as a craft project. Arts & Craft stores have responded by offering a wide variety of craft papers in various colors, textures and printed patterns. Marbled papers are popular for these applications. Such papers draw significantly on patterns created by Islamic artists in a process known as ebru, in which oil paints are layered in decorative patterns on the surface of a water bath. The paints are then transferred to paper by carefully laying the paper on top of the patterned oil. Highly skilled artisans can create impressive pictures using the ebru technique. The process is described in detail online at What is Ebru Art? Exploring the Ancient Techniques of “Painting on Water” by By Kelly Richman-Abdou, October 11, 2017, at mymodernmet.com.

Watercolor and Gouache

Watercolors are paints composed of a pigment combined with a binder, usually gum arabic, that are designed to be miscible with water. Gouache is very similar to watercolor but the paint is opaque rather than translucent. Because of the absorbent nature of paper, artists have used the ability of watercolor paints to spread into wet paper to achieve appealing diffuse effects particularly in rendering skies and water. Details may be introduced into watercolor paintings by scratching thin lines into them to reveal the color of paper beneath.

Pastels

Pastels are composed of a pigment dispersed in binder such as gum arabic or gum tragacanth and are usually used in stick form. Oil pastels are similar but the pigment is dispersed in a nondrying oil and wax. Unlike watercolors or oil paints, pastels are normally not intended to be mixed with a vehicle (i.e., water, drying oil or solvent) as are watercolors and oil paints, although some modern pastels have been prepared that have some water solubility so that they manipulated after applying to the paper. Soft pastels have a high proportion of pigment to binder making them easy to blend and smudge after application, while hard pastels, in contrast, have a higher portion of binder and can be used more like a pencil to achieve fine details.

Drawings

Charcoal, Pencil, Chalk, Pen & Ink

Drawings have been made using a variety of materials that are capable of producing lines of varying thicknesses and shapes. These include charcoal, pencils (both black and colored), chalk and pen & ink.

Charcoal - Charcoal is prepared by heating wood in an oxygen-poor atmosphere so that the organic matter carbonizes rather than burns. Charcoal sticks known as vine charcoal or willow charcoal, are produced by charring grape vines or willow sticks, respectively, directly a kiln in the absence of air. Charcoal pencils and charcoal blocks are made from powdered charcoal that is mixed with a binder and compressed, with the former being encased in wooden sleeve as are other pencils.

Pencils - Pencils are made by wrapping a pigment stick with a wood casing. 'Lead' pencils don't actually contain lead - even though the core of the pencil is known as a pencil lead, is made of graphite (see Graphite), which is a soft material that allows the layers of carbon atoms to slip easily over one another and thereby be rubbed off onto the paper or other material. Pencils come in varying degrees of hardness that are rated by how easily the graphite will transfer to paper. Harder pencils will produce finer lines. Colored pencils, of course, do not contain graphite, which is always black. Instead they contain a core that contains the pigment embedded in a was or oil-based material.

Chalk - Traditionally, chalk is made from the mineral calcite (limestone), which is the composed of calcium carbonate, CaCO3. Modern chalks may also be made from dehydrated calcium sulfate (found in nature as the mineral gypsum, CaSO4·2H2O). In either case, the minerals are slurried with water to make a thick paste and then fashioned into sticks for ease in drawing. After drying in an over, the sticks are cut to their final lengths.

Inks - Inks are pigments dispersed in a liquid, often water or alcohol, or a gel medium for writing on paper or parchment. Black inks can be made used soot, or carbon black, or graphite. A common ink in the middle ages was iron gall ink. Iron gall ink was prepared by mixing ferrous sulfate (FeSO4) with an extract from galls on oak or other trees. This extract contains tannins, and the result is an iron tannate complex. Upon exposure to air, the Fe2+ ions would oxidize to Fe3+ and the resulting ferric tannate ink would become insoluble in water. Iron gall ink often caused deterioration of the parchment or paper on which it was used owing to its acidity.

Prints

Woodblocks prints, Itaglio prints, and Lithography

There are several methods available for transferring an image that is created on a wood, metal or stone support onto a piece of paper. These include wood block prints, etchings and lithography and all are different in their basic approach to printmaking. All have the advantage of being able to make multiple copies from the support material, and the images produced are mirror images of that produced on the support.

Wood block printing

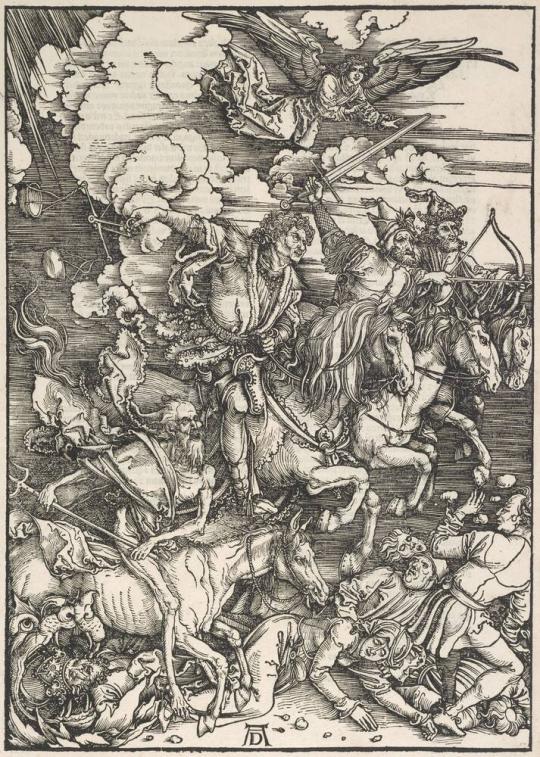

To prepare a woodblock print, an image is drawn on a simple block of wood and the areas that are not to receive ink are removed by carving or chiseling them from the surface. The raised image is then coated with ink and pressed onto the paper support. The advantage of woodblock printing is that wood is cheap and easily carved to produce the relief images. On the other hand, wood is not as durable as metal or stone supports.

Intaglio prints

Intaglio prints are produced by mechanically by chemically creating an image in a metal plate. Engraving is a mechanical method by which the image to be printed into the metal surface, such as a plate of zinc or copper, is engraved with a tool known as a burin, or using a needle (drypoint). Mezzotints was a technique using a tool known as a rocker with multiple small teeth that produced many tiny indentations resulting in a textured area rather than individual lines. The image could alternatively be produced by etching. In this method, the metal support is covered with an impervious coating such as a hard wax. The image is then drawn into the wax with a metal stylus to selectively remove the wax and expose the metal layer underneath. An etching equivalent to the mezzotint is the aquatint, in which a powdered rosin is applied to the metal plate to create textured areas. As with the regular etching process, the rosin is impervious to the acid and protects the areas underneath is. Once the image has been created, the metal plate is immersed in acid that is able to etch the metal where the wax has been removed or areas where the rosin has been applied. This process creates recessed areas in the plate. The wax and/or rosin is then removed using an appropriate solvent and the plate is dried. In either the engraving or etching methods, ink is applied to the plae and fillas the recessed image. Excess ink remaining on the surface of the plate is wiped off, paper is then pressed onto the plate forcing it into the recessed areas containg the ink, and the inked image is transferred to the paper. As with woodblock prints, the image is a mirror image of that drawn originally.

Lithography

In original lithography a stone that reacts with acid, such as limestone (See Gems & Minerals) is treated similarly to the method used for producing an etching. In this case, however, a hydrophobic coating such as oil, fat or wax is used to produce directly the desired image on the stone. The stone is then treated with acid to etch the areas not coated. Afterwards the coating material is removed with a solvent leaving the image to be printed in relief. Water is then applied, penetrating the areas that were etched. This is followed by coating the stone with ink, but the oil-based ink used will not adhere to the etched areas that are filled with water. The stone is then pressed against the blank paper and the relief image is transferred as a reverse image, as for both woodblock prints and etchings. In recent times, however, the process has evolved so that the image is made by applying a polymer to a metal or plastic plate. This plate can be printed directly to produce a reverse image as before, or the polymer image can be transferred to another support such as a rubber backing. In so doing, the image is re-reversed and an offset print is obtained. Offset printing is currently the major means by which prints are produced.

Color printmaking

Color prints could be obtained in a time consuming process in which each print was hand colored. In this way, the iconic prints of James Audubon were created.

Shortcuts

Credits for the Header Image

- Roses and Nightingale, Muhammad Baqir, Persian (active 1740s-1800s), Ink and Watercolor on paper, from the Collection of the Museum of Fine Arts Houston, Figt of Nasrin and Abolala Soudavar, Public Domain.

- A Windmill, Thomas Girtin, British (175-1802), Watercolor and graphite on paper, ca. 1800, from the Collection of the Museum of Fine Arts Houston, Public Domain.

- Study for an Advertising Poster: Lance Parfum "Rodo"Alphonse Mucha (Czech, 1860 - 1939), 1896, and brush and ink on wove paper, from the Collection of the Museum of Fine Arts Houston, Public Domain.

- Boat-tailed Grackle Robert Havell, Jr., American, 1793-1878, aftern John James Audubon, 1834, Aquatint, etching, engraving, and watercolor on wove paper, from the Collection of the Museum of Fine Arts Houston, The Bayou Bend Collection, gift of Miss Ima Hogg, Public Domain.

Department of Chemistry

Houston, TX

6100 Main St., Houston, TX 77005-1827 | Mailing Address: P.O. Box 1892, Houston, TX 77251-1892 713-348-0000 |